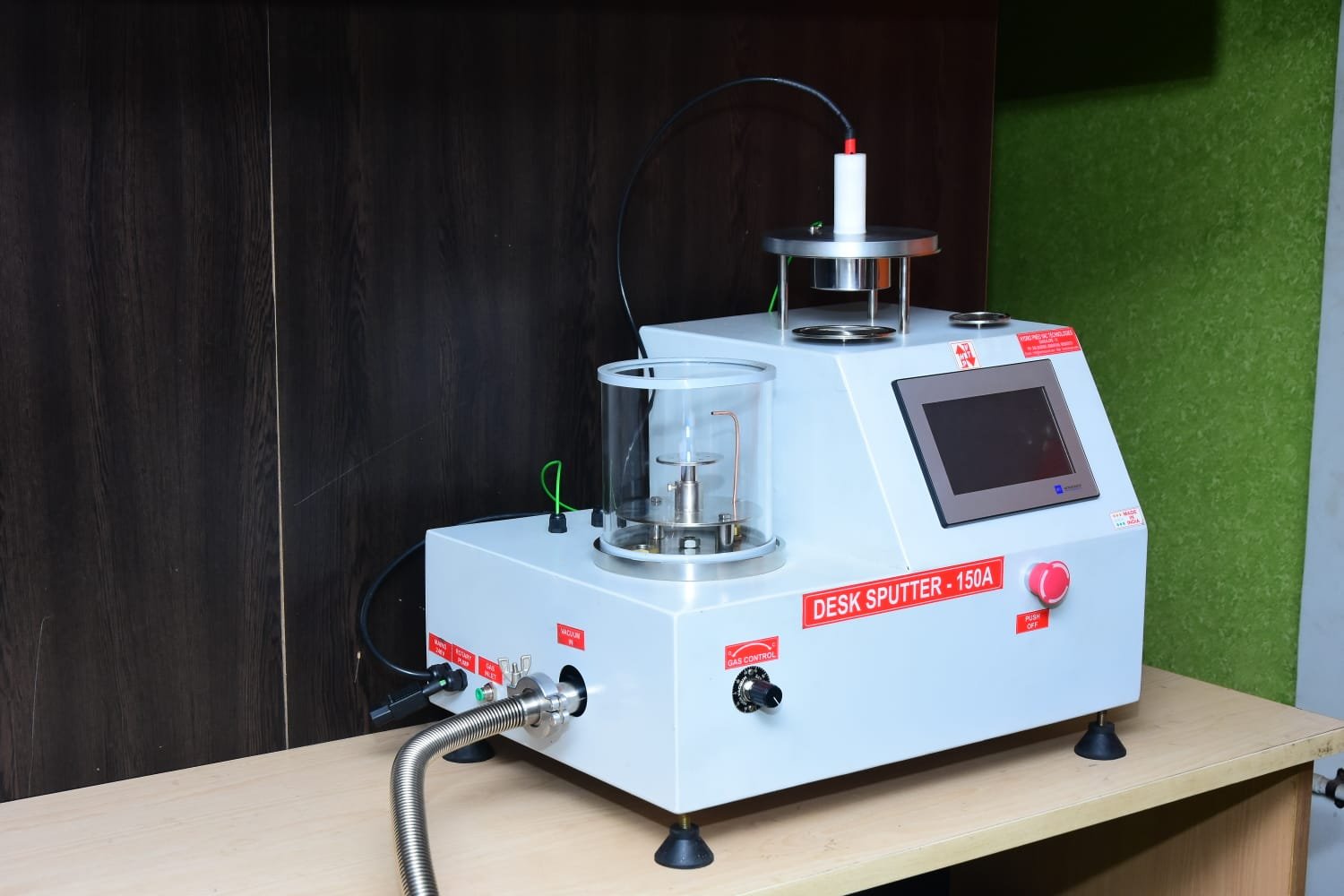

The Table Top Sputter Coater is a compact, high-vacuum DC magnetron sputtering system designed for depositing uniform, ultra-thin metal coatings on non-conductive samples to enhance imaging in Scanning Electron Microscopy (SEM). Built to meet the needs of material science, nanotechnology, forensic, and academic research labs, this unit ensures consistent results with minimal footprint and intuitive operation.

This sputter coater operates under a high-vacuum environment using a DC magnetron source to deposit conductive metals such as gold (Au), platinum (Pt), and palladium (Pd). It ensures superior sample conductivity, minimizes charging effects, and significantly improves contrast and resolution in SEM images.

| Specification | Details |

|---|---|

| Sputtering Method | DC Magnetron Sputtering |

| Chamber Material | Stainless Steel |

| Vacuum Level | 10⁻² to 10⁻³ mbar |

| Target Diameter | 50 mm (2 inches) |

| Power Output | 0 – 100 Watts (adjustable) |

| Deposition Time | 1 – 999 seconds (programmable) |

| Sputtering Pressure | 0.01 – 1 mbar (adjustable) |

| Control Interface | Digital Display with Real-Time Monitoring |

| Vacuum Pump Compatibility | Rotary Pump (100 L/min), Turbo Molecular Pump (optional) |

| Compatible Metals | Au, Pt, Pd, Ir, Cr, Ag, Al |

| Sample Stage | Rotating holder, up to 50 mm diameter samples |

| Power Supply | 220V AC ±10%, 50/60 Hz |

| Dimensions (L × W × H) | 350 mm × 370 mm × 420 mm |

| Weight | 22 kg (approx.) |

| Safety Features | Overcurrent protection, vacuum interlock, emergency stop, over-temperature shutdown |

Compact Design

Dimensions: 350 mm x 370 mm x 420 mm – takes up minimal bench space, ideal for use in academic, research, and industrial laboratories.DC Magnetron Sputtering Technology

Enables high-efficiency, uniform metal film deposition critical for SEM imaging and thin-film applications.High-Vacuum Stainless Steel Chamber

Rugged and corrosion-resistant chamber supports stable vacuum levels between 10⁻² to 10⁻³ mbar, compatible with rotary or turbo pumps.Standard Target Diameter

Supports 50 mm (2 inch) metal sputtering targets for standard research and coating applications.Fully Adjustable Coating Parameters

Power Output: 0 – 100 Watts

Deposition Time: 1 – 999 seconds (programmable)

Sputtering Pressure: 0.01 – 1 mbar (adjustable with precision needle valves)

Digital Control Interface

Live real-time display of coating power and time

Simple, user-friendly digital navigation for setting parameters

Vacuum Pump Compatibility

Rotary Pump: 100 L/min capacity

Turbo Molecular Pump: Available as an optional upgrade for high-vacuum operation

Broad Metal Target Compatibility

Compatible with a wide range of metals including:

Gold (Au), Platinum (Pt), Palladium (Pd), Iridium (Ir), Chromium (Cr), Silver (Ag), Aluminum (Al)Rotating Sample Stage

Provides 360° uniform coating and can hold multiple samples up to 50 mm in diameter.Efficient Power Supply

Operates on 220V AC ±10%, 50/60Hz, offering low energy consumption and compatibility with global lab standards.Comprehensive Safety Systems

Includes multiple built-in safety mechanisms:Overcurrent protection

Vacuum chamber interlock

Emergency stop button

Over-temperature auto shutdown

Lightweight and Portable

Approximate weight: 22 kg, making it easy to install, relocate, and maintain on standard laboratory benches.

Scanning Electron Microscopy (SEM) Sample Coating

Uniform metal deposition on non-conductive specimens (biological, polymers, ceramics, geological samples) to improve secondary electron imaging.Nanotechnology and Thin Film Fabrication

Ideal for research involving nanoparticles, MEMS, microelectronics, and functional surface development.Material Science & Metallurgical Research

Used for creating high-resolution images of crystalline structures, grain boundaries, and fracture surfaces.Forensic Science & Trace Evidence Analysis

Prepares microscopic fibers, gunshot residues, and other samples for high-detail SEM investigation.Academic Research and Teaching

Popular in universities and training centers for hands-on learning in surface science, materials characterization, and microscopy.