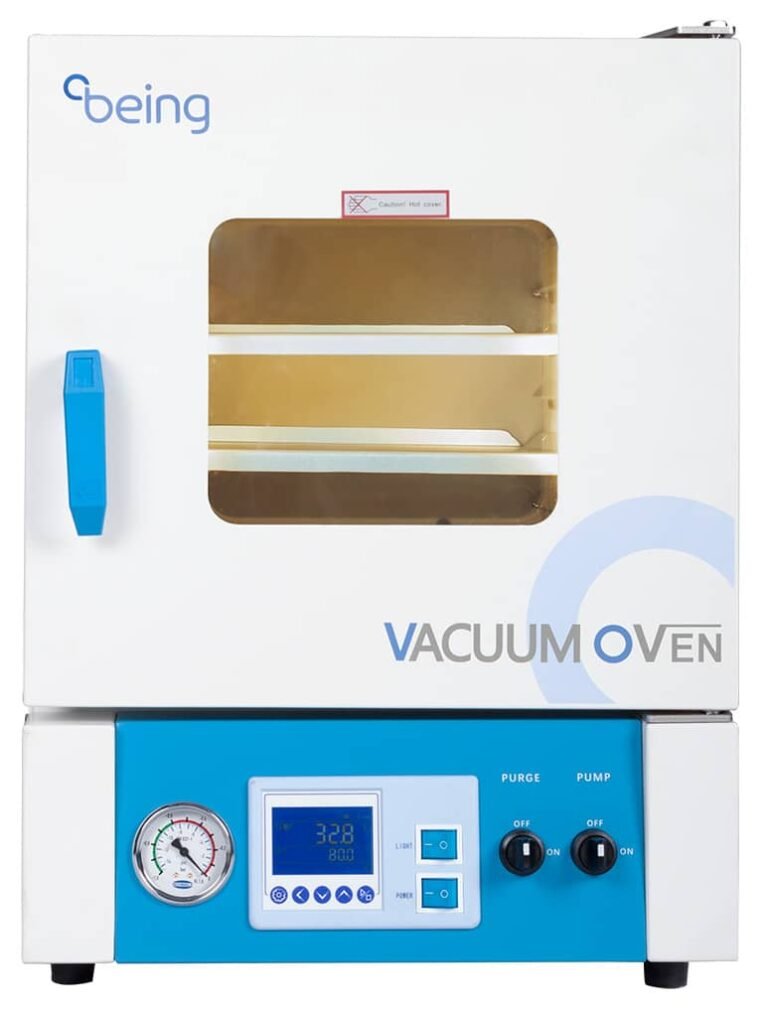

Laboratory Vacuum Oven – Precision Drying & Sterilization for Scientific Applications

A Laboratory Vacuum Oven is a high-precision drying and sterilization system designed for moisture removal, outgassing, and heat-sensitive material processing under controlled low-pressure environments.

Equipped with vacuum chamber technology, temperature stability, and an inert gas supply option, it provides chemical-free drying, ensuring safe and efficient sample preparation in pharmaceutical, biomedical, and industrial research laboratories.

With digital control features, user-friendly operation, and contamination prevention systems, the vacuum drying oven is essential for granular material processing, powder sample drying, and thermal treatment of laboratory specimens

Key Features of Laboratory Vacuum Oven

Precision Temperature Control System

- Digital PID controllers ensure accurate and stable temperature settings.

- Uniform heat distribution for consistent drying without overheating samples.

Vacuum Chamber for Low-Temperature Drying

- Removes moisture, volatile compounds, and solvents without sample degradation.

- Prevents oxidation and contamination, making it ideal for sensitive materials.

Multiple Vacuum Pump Compatibility

- Supports oil-sealed, dry scroll, and rotary vane vacuum pumps.

- Ensures faster drying times and improved efficiency.

Inert Gas Supply for Safe Processing

- Allows nitrogen or argon purging to prevent sample oxidation.

- Maintains controlled environmental conditions for high-purity sample drying.

Chemical-Free Drying & Sterilization

- Provides non-toxic, chemical-free sterilization of laboratory tools and medical instruments.

- Ensures contamination-free sample handling.

Energy-Efficient Design with Uniform Heating

- Low-energy consumption technology reduces operational costs.

- Double-layered insulation maintains consistent temperature control.

Digital Touchscreen & Programmable Settings

- Features LED/LCD digital control panels for easy programming and real-time monitoring.

- Pre-set drying cycles and data logging improve efficiency.

High-Temperature Vacuum Oven Models Available

- Standard models operate at 50°C to 250°C, with high-temperature models up to 500°C.

- Supports advanced research and industrial material testing.

Technical Specifications of Laboratory Vacuum Oven

| Feature | Specification |

|---|---|

| Temperature Range | 50°C to 250°C (High-Temperature Models Available) |

| Vacuum Range | 0.1 mbar to 760 Torr |

| Control System | Digital PID Temperature Controller |

| Chamber Material | Corrosion-Resistant Stainless Steel |

| Drying Time Optimization | Programmable Timed Drying Cycles |

| Inert Gas Purging | Compatible with Nitrogen & Argon |

| Energy Efficiency | Low Power Consumption & Insulated Design |

| Applications | Pharmaceutical, Industrial, Material Science, Research Labs |

Applications of Laboratory Vacuum Oven

Pharmaceutical & Biotechnology Research

- Used for drug formulation drying, powder sample sterilization, and solvent evaporation.

- Ensures safe processing of heat-sensitive biomaterials.

Industrial & Material Science Applications

- Ideal for polymer curing, composite material drying, and semiconductor processing.

- Used in electronics manufacturing for moisture-sensitive component drying.

Food & Beverage Processing

- Supports low-temperature dehydration of food products and botanical extracts.

- Ensures nutrient preservation and extended shelf life.

Forensic & Environmental Testing Laboratories

- Facilitates moisture content analysis in soil, forensic samples, and chemical residues.

- Used for decontamination of lab samples before testing.

Medical & Sterilization Techniques

- Used in medical research for non-thermal sterilization of surgical instruments and lab tools.

- Prevents bacterial and fungal contamination in biological studies.

Why Choose The Laboratory Vacuum Oven

Advanced Vacuum Technology for Faster Drying

- Low-pressure vacuum system speeds up moisture removal without overheating.

- Prevents sample oxidation, degradation, and contamination.

Highly Precise & Consistent Temperature Control

- PID-controlled temperature system maintains uniform heating.

- Ensures stable drying conditions for research and industrial applications.

Versatile Compatibility with Vacuum Pumps & Gas Supply

- Supports various vacuum pump models for customized drying solutions.

- Inert gas purging feature for oxygen-sensitive materials.

User-Friendly Interface with Digital Controls

- Touchscreen display with programmable settings for automated drying cycles.

- Includes real-time monitoring of temperature, pressure, and drying time.

Energy-Efficient & Low-Maintenance Design

- Insulated chamber reduces heat loss, minimizing energy consumption.

- Corrosion-resistant stainless steel construction ensures long-term durability.